Detailed Explanation of the Function of Impact Crusher Rotors

As the core of mining crushing equipment, the impact crusher is widely used in the global mining industry due to its high efficiency and energy saving. Internally, the rotor is undoubtedly the "heart" of the entire machine, directly determining crushing efficiency, finished product quality, and equipment lifespan.

As a mining crushing equipment manufacturer with 20 years of professional experience, we are committed to providing global customers with comprehensive crushing solutions. Today, we will delve into the key functions, technological advantages, and application practices of the impact crusher rotor.

| Key Words | Limestone Crusher |

|---|---|

| Product Model | PF Impact Crusher |

| Feed Size | ≤700mm |

| Motor Power | 45-355kw |

| Capacity | 15-800t/h |

| Core Design | The heavy-duty rotor has high inertia, enabling it to crush harder materials and operate more smoothly. |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

I. Overview of the Core Functions of the Impact Crusher Rotor

The rotor is the core component of the impact crusher that converts the motor's kinetic energy into crushing force. Through high-speed rotation (linear velocity up to 60-80 m/s), it drives the hammers to violently impact the material, causing the material to collide and rub within the crushing chamber, thus crushing it. Its main functions include:

1. Kinetic Energy Conversion: Converting the rotational kinetic energy provided by the motor into impact crushing energy.

2. Material Acceleration: Imparting extremely high velocity to the material, causing it to collide at high speed with the impact plate, liner, or other materials.

3. Particle Size Control: Adjusting parameters such as rotor speed and hammer gap affects the output particle size distribution.

4. Particle Shape Influence: Optimizing rotor design yields more cubic finished products and reduces the content of needle-like and flaky particles.

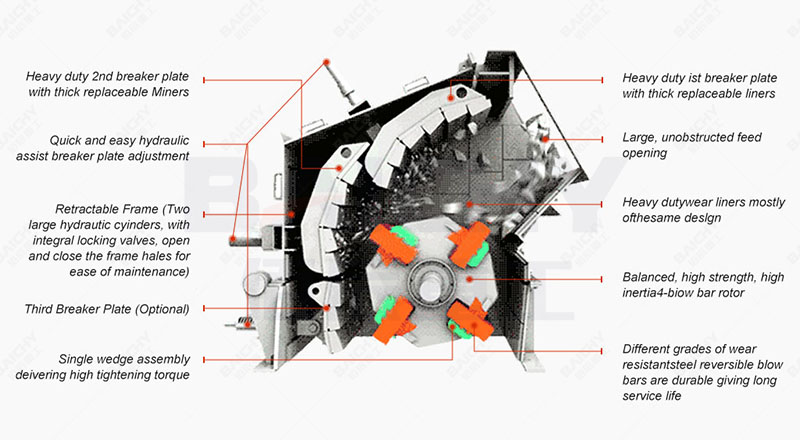

PF Impact Crusher Structure Diagram

II. Our Rotor's Technical Advantages and Innovative Design

Based on 20 years of manufacturing experience and technological accumulation, our impact crusher rotor possesses the following outstanding advantages:

• Heavy-Duty Design: Utilizing a high-strength alloy steel integral forging or segmented welded structure, optimized through finite element analysis, ensuring stable operation under high speed and high load, extending service life by over 30%.

• Dynamic Balance Calibration: Calibrated on a professional dynamic balancing machine, residual imbalance reaches the G6.3 standard, ensuring smooth operation, low vibration, and reduced bearing wear.

• Modular Hammers: The hammers feature a symmetrical design, allowing for reversible use after wear, doubling utilization. Mechanical or hydraulic fastening devices ensure quick and safe replacement, reducing downtime.

• Differentiated Design: Customized rotor solutions with varying speeds, hammer disc structures, and hammer materials are available to address different material characteristics (e.g., high-hardness granite, medium-hardness limestone, or sticky materials).

• Intelligent Monitoring: Optional vibration sensors and temperature monitoring points enable real-time monitoring of rotor operation and predictive maintenance.

III. Comprehensive Application Solutions

Our impact crushers and their core rotors are widely used in:

• Aggregate Production: Providing high-quality coarse, medium, and fine aggregates for construction, highways, and railways, with excellent particle shape and continuous gradation.

• Mining Crushing: Suitable for medium and fine crushing of various metallic and non-metallic ores such as iron ore, copper ore, gold ore, limestone, granite, and basalt.

• Recycling Resources: Crushing construction waste and concrete waste for resource utilization, with a rotor offering enhanced impact resistance.

• Industrial Powder Preparation: Providing raw material preparation for power plant desulfurization, cement production, metallurgy, and other industries.

IV. Global Project Case Studies

1. A Large-Scale Granite Aggregate Project in Southeast Asia:

Client Needs: 800 tons per hour, finished product for high-standard highway surface courses. We configured a heavy-duty impact crusher with a high-speed rotor design to ensure sufficient crushing force. Result: The finished product contained over 95% cubic particles and less than 8% needle-like or flaky particles, fully meeting the requirements for high-end aggregates. The equipment has been running continuously for over two years without significant rotor wear.

2. Mid-Crushing System Upgrade at a Copper Mine in Central Asia:

The original equipment had low crushing efficiency and high energy consumption. We replaced it with a custom-designed high-wear-resistant alloy hammer rotor and optimized the crushing chamber shape. After the upgrade, the system's processing capacity increased by 25%, energy consumption decreased by 15%, and the hammer's lifespan increased from 15 days to 45 days, significantly reducing operating costs.

3. A Construction Waste Recycling Project in Europe:

The material composition was complex, containing foreign objects such as reinforcing steel bars. We provided an impact crusher with a reinforced shaft and an overload protection device. Its rotor possesses extremely high impact resistance. When encountering unbreakable foreign objects, the hydraulic opening device can quickly open and discharge the foreign objects, ensuring the continuous and stable operation of the production line.

V. Frequently Asked Questions (FAQ)

Q1: How often does the rotor typically need maintenance or replacement?

A: This depends on the abrasiveness of the material being processed, the feed particle size, and the production intensity. Generally, when crushing moderately abrasive materials, the hammer life is 300-600 hours, and the rotor body can be used for several years. We recommend regularly checking the wear of the hammers, the locking device, and the rotor body.

Q2: How do I determine if the rotor needs dynamic balancing?

A: When the equipment vibrates significantly more during operation, the bearing temperature rises abnormally, or abnormal noises at specific frequencies occur, it may indicate rotor imbalance or uneven wear of components. The machine should be stopped immediately for inspection, and dynamic balancing calibration should be considered.

Q3: Are your rotors compatible with other brands of impact crushers?

A: We can customize production and adapt the equipment based on the drawings and technical parameters you provide, ensuring a perfect match between the rotor and your frame and transmission system. We have extensive experience in non-standard customization.

Q4: What special design features does the rotor have when crushing wet, sticky materials?

A: For wet, sticky materials, we use a larger rotor body and a smaller blind plate area to increase the crushing chamber capacity and reduce the risk of material adhesion and blockage. Additionally, a heating device can be installed at the feed inlet.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.