Dry Ball Mill Applications and Advantages Analysis

Dry ball mills, as one of the core pieces of equipment in the crushing and grinding stages of mining, play a crucial role in mineral processing. Especially in areas with scarce water resources or in processing scenarios with strict requirements on product moisture content, dry ball mills, with their unique process advantages, have become the preferred grinding solution for many mining companies. Compared to wet ball milling, dry ball milling directly processes dry materials, avoiding subsequent dewatering and drying steps, significantly reducing system energy consumption and operating costs. It is particularly suitable for industries such as cement, silicate products, new building materials, refractory materials, non-ferrous metal beneficiation, and glass and ceramics production.

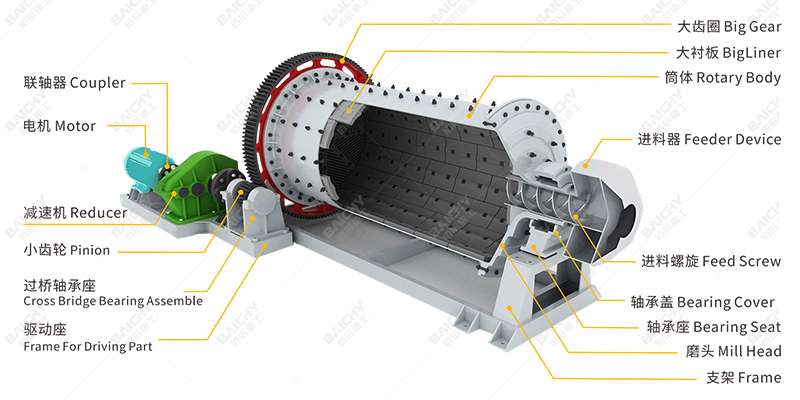

Ball mill structure diagram

Equipment Overview: Working Principle and System Composition

The working principle of a dry ball mill is based on the combined action of centrifugal force and friction. The cylinder rotates driven by a transmission device, and the grinding media (steel balls, steel segments, etc.) inside are lifted to a certain height by centrifugal force before falling, impacting and grinding the material inside the cylinder, thus achieving the crushing and refinement of the material. Its main systems include:

1. Feeding System: Provides a stable and uniform supply of material to the mill.

2. Cylinder and Liners: The cylinder is the grinding space, lined with wear-resistant liners to protect the cylinder and improve grinding efficiency.

3. Transmission System: Includes motor, reducer, gears, etc., providing rotational power.

4. Discharge and Classification System: The ground material is discharged through the discharge grate, often forming a closed-loop system with classification equipment (such as air classifiers, cyclone separators) to control product fineness.

Core Advantages: Why Choose Dry Ball Milling?

Based on our company's 20 years of experience in mining equipment manufacturing, we have summarized the significant advantages of dry ball mills in mineral processing:

- Strong Adaptability: Particularly suitable for arid and water-scarce areas, or processing processes where the material itself is sensitive to water (such as cement raw materials, coal powder preparation).

- Low Investment and Operating Costs: Eliminates the need for auxiliary equipment such as concentration, filtration, and drying required in wet processes, resulting in a simpler process, smaller plant footprint, and lower daily maintenance costs. - Easily controllable product moisture content: Directly produces dry powder, facilitating storage, transportation, and subsequent processing, meeting the strict requirements for low moisture content in certain industries.

- Environmentally friendly: No wastewater is generated or discharged, and dust can be centrally processed through a high-efficiency dust collection system (such as a bag filter), achieving clean production.

- Easy adjustment of product fineness: By combining with air classification equipment, the product fineness can be flexibly adjusted to meet different process requirements.

Ball mill customer site

Application Case: Successful Practice Demonstration

Case: A large-scale iron ore tailings reprocessing project

The client wanted to reprocess accumulated iron ore tailings to recover iron concentrate. Due to the arid region in Northwest China, where water resources are extremely precious, the client chose a dry grinding-dry magnetic separation process. Our company designed and provided a Φ3.2×6.5m large-scale dry ball mill, forming a closed-circuit system with a high-efficiency turbine classifier. The mill uses specially designed corrugated and classifying liners to optimize the movement trajectory of the grinding media. After the project was implemented, the system operated stably, grinding the tailings to a fineness of 75% passing -200 mesh, creating ideal conditions for subsequent dry magnetic separation. Ultimately, high-efficiency recovery of iron elements was achieved, and the entire process generated no wastewater, resulting in significant economic and environmental benefits.

Related Equipment Recommendations (from 20 years of manufacturer experience)

An efficient dry ball mill system often requires the coordination of supporting equipment. We recommend:

1. High-efficiency quantitative feeder: Ensures the mill is "fed sufficiently and evenly," which is fundamental to stable operation.

2. Dynamic classifier/separator: Achieves closed-circuit grinding, strictly controls product fineness, avoids over-grinding, and ensures energy efficiency and high output.

3. Pulse bag filter: Handles dust from the mill outlet and system dust points, ensuring a clean working environment, meeting environmental requirements, and recovering the finished product.

4. Intelligent control system: Integrates monitoring of electric ear (grinding sound measurement), bearing temperature, pressure, etc., to achieve automatic control of mill load and optimize grinding efficiency.

Frequently Asked Questions (FAQ)

Q1: What are the main criteria for selecting between a dry ball mill and a wet ball mill?

A: The main considerations are material properties, subsequent process requirements, and water availability. If the material is sensitive to water, or if subsequent processes involve dry separation (such as dry magnetic separation or electrostatic separation), or if the plant is located in an arid region with limited water resources, dry ball milling should be prioritized. If the material needs to be dispersed in water, or if subsequent processes involve wet methods such as flotation, or if there are extremely strict limitations on dust control, then wet ball milling is more suitable.

Q2: Dry ball mills generate a significant amount of dust during operation. How can this be effectively addressed?

A: Dust control is a key design focus of modern dry ball milling systems. Effective solutions include: 1) Ensuring the airtightness of the mill body and connections; 2) Installing enclosed covers at dust-generating points such as the discharge port and conveyor belt transfer points; 3) Using a high-efficiency pulse bag filter, which is the most crucial measure, achieving a dust removal efficiency of over 99.9%; 4) Maintaining the system under a slight negative pressure to prevent dust leakage.

Q3: How can the grinding efficiency of a dry ball mill be improved and energy consumption reduced?

A: The key to improving efficiency lies in: 1) Optimizing the grinding media: Scientifically proportioning steel balls of different diameters based on the feed and product particle size, and replenishing them regularly; 2) Adopting a closed-circuit system: Working in conjunction with classification equipment to promptly remove qualified fine powder and reduce the "cushioning layer" effect; 3) Using wear-resistant liners: Maintaining the surface shape of the liners to optimize the lifting capacity of the material and steel balls; 4) Controlling the optimal material-to-ball ratio and filling rate; 5) Introducing an automated control system to optimize the mill loading in real time.

Dry ball mills are efficient, flexible, and environmentally adaptable key equipment in the field of mineral processing. Proper selection, reasonable configuration, and scientific maintenance can bring significant economic and environmental benefits to enterprises. As a mining equipment manufacturer with 20 years of technological expertise, we are committed to providing customers with personalized dry grinding solutions, from single machines to complete systems, to support the efficient, green, and sustainable development of the global mining industry.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.