In the mining and aggregate processing industries, gyratory crushers and cone crushers are core equipment in the medium and fine crushing stages. Because they both have a cone shape, many people easily confuse the two. However, they differ fundamentally in structure, working principle, applicable scenarios, and cost. Choosing the wrong equipment can directly impact production line efficiency, finished product quality, and operating costs.

Gyratory Crusher PDF, Download ↓↓↓

This article will delve into the core differences between gyratory crushers and cone crushers to help you make an informed decision.

I. Overview of Core Differences

Before ping into the details, let's quickly understand the main differences between the two using a table.

| Features | Gyratory Crusher | Cone Crusher |

| Installation Method | Horizontally mounted on the main shaft, suspended from the top by a hanger | Vertically mounted on the main shaft, supported at the bottom by an eccentric sleeve |

| Feed Size | Large (can handle boulders over 1 meter in diameter) | Medium to small (typically less than 250mm) |

| Processing Capacity | Very high (up to 10,000 tons per hour or more) | High (typically below 1,000 tons per hour) |

| Discharge Size | Relatively coarse, limited adjustment range | Relatively fine and uniform, easy to adjust precisely |

| Cost | High (large equipment, complex structure) | Relatively low (more compact structure) |

| Application Stage | Primary crushing (coarse crushing) | Secondary or tertiary crushing (medium/fine crushing) |

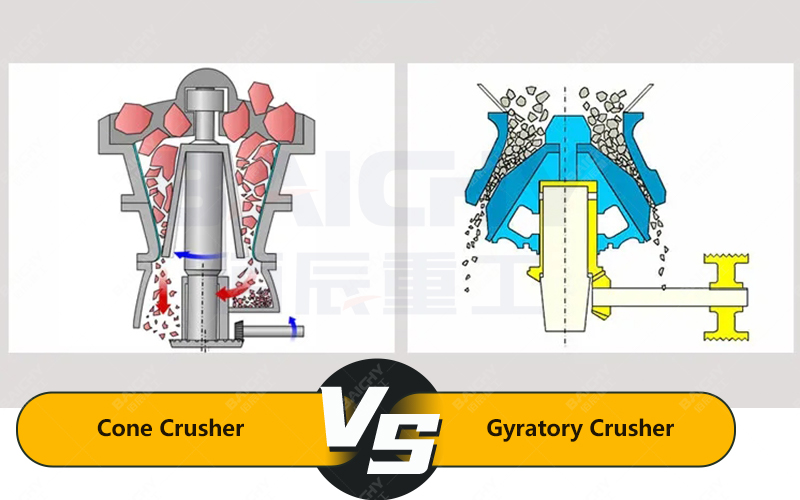

II. Working Principle and Structural Differences

1. Gyratory Crusher A gyratory crusher can be viewed as a "giant funnel." Its core components are a fixed outer cone shell and a moving inner cone (moving cone). The upper end of the moving cone is suspended from a crossbeam, and the lower end is inserted into an eccentric sleeve. When the motor drives the eccentric sleeve to rotate, the moving cone undergoes a gyratory oscillation, constantly approaching and moving away from the fixed cone, thus compressing and crushing large pieces of material falling into the chamber.

• Features: Large inlet, capable of directly processing raw ore from the mine, it is the "main force" in the coarse crushing stage of the production line.

2. Cone Crusher The bottom of the moving cone of the cone crusher is directly supported by a large eccentric sleeve, while the top is a flexible spherical hinge. During operation, driven by the eccentric sleeve, the moving cone undergoes a combined revolution and rotation along the inner wall of the crushing chamber. This motion causes the material to be subjected not only to compression but also to strong bending and shearing forces within the crushing chamber.

• Features: Possesses a longer crushing chamber and a more refined adjustment mechanism, particularly suitable for crushing medium-sized materials into well-shaped, uniformly sized finished products, making it an ideal piece of equipment for medium and fine crushing.

III. How to Choose: Scenario Determines Everything

The choice of equipment depends entirely on your production needs and budget.

• Choose a gyratory crusher if:

◦ Your raw material is very large rubble or ore (>1 meter).

◦ You require extremely high throughput and it's the first crushing stage in your production line.

◦ You don't have high requirements for the output particle shape; it's mainly for preparing for the next crushing stage.

• Choose a cone crusher if:

◦ Your feed is already medium-sized material (<250mm) after coarse crushing by a jaw crusher or gyratory crusher.

◦ You need to obtain a final product with excellent particle shape and controllable particle size (such as aggregate for high-grade concrete).

◦ Your budget is relatively limited, or installation space is constrained.

Simply put, a gyratory crusher is an expert in coarse crushing of "large blocks," while a cone crusher is a fine crushing expert for creating "high-quality aggregate." They are complementary processes in the production line, not simple substitutes. Understanding the differences between them is the first step in building an efficient and economical crushing production line.