|

Equipment configuration

|

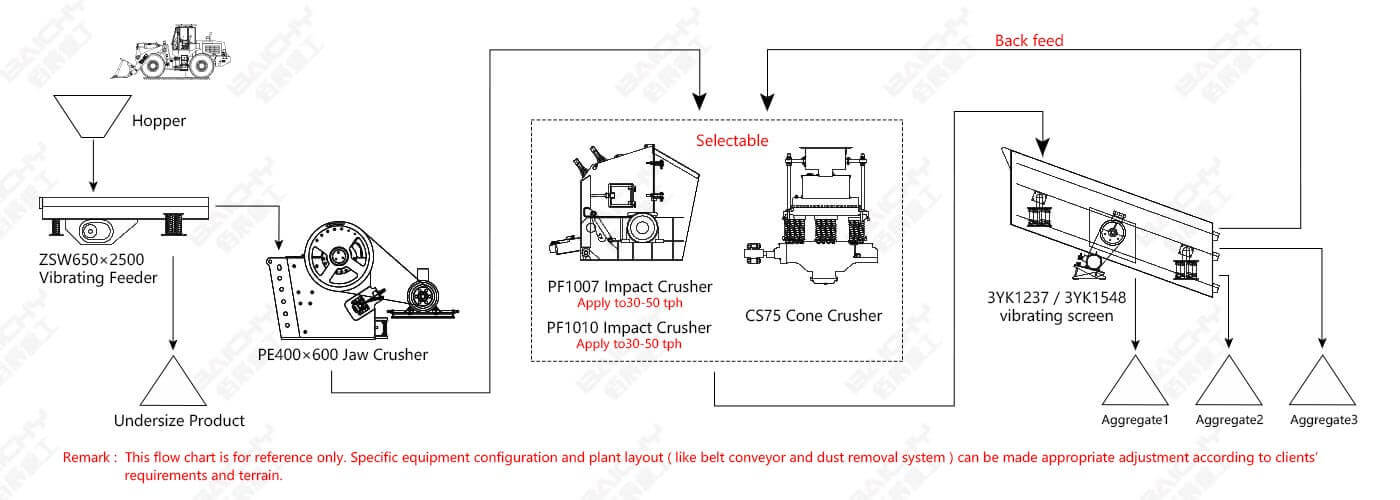

Hopper, ZSW650x2500 vibrating feeder, PE400x600 jaw crusher, PF1007impact crusher (PEX250x1000 jaw crusher), Vibrating screen, Belt conveyor. |

|

Raw materials

|

Limestone, Granite, Basalt, Quartz, River stone etc. |

|

Feed Size

|

Less than 350mm |

|

Capacity

|

40-60t/h |

|

Finished product

|

3-100mm |

|

Application

|

produce aggregate of limestone, granite, basalt, river stone, marble, iron ore, dolomite, quartz, slag etc, which is widely applied for hydropower, construction, highway, railway, airport runway, civil engineering projects and etc. |

|

Advantages

|

High production efficiency and low operating cost; Large output, uniform particle size of finished stones and good grain shape, which meets the requirements of national high-speed materials. |

With the features of high efficiency and energy saving, PCZ heavy-duty hammer crusher adopts mature technologies, which can achieve the once-molding crushing effect. Particularly for medium hardness materials and fragile materials, this kind of crusher can achieve a perfect fine-crushing effect. For meeting the different requests of customers, it can adjust the discharge size by adjusting the gap of the grate plate.

Spring cone crushers are generally used in the medium and fine crushing links of mine crushing, and are mainly used in the secondary crushing and tertiary crushing links in metal mines and construction sandstone processing. Because of their strong crushing capacity and large output, they are more used in the Crushing of hard materials.

Crushing equipment is the foundation of the stone production line, and having a good sand and gravel production line is the guarantee of wealth. Regarding a 40-60t/h sand and gravel production line, how do we configure it?

Limestone is a common raw material for producing stones. The main component is calcium carbonate, with a Mohs hardness of 3-4. It is a soft material, widely distributed, and easy to mine. The processed stones can be used to configure concrete, mortar, road paving, etc., and have a wide range of applications, the market demand is great.

How to configure limestone crushing equipment? Baichy recommends a plan for you, you can choose according to your own situation.

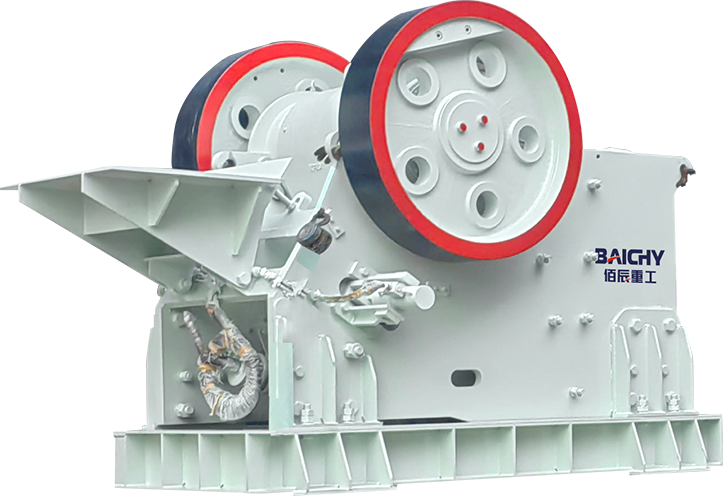

PE400x600 Jaw Crusher

Limestone coarse crushing equipment has a strong crushing force, and the feeding particle size of the equipment is 0-350mm. Because it is primary crushing equipment, there are many models and a large natural production capacity range. Between 15-60t/h, the crushing force of the jaw crusher is higher than that of the jaw crusher. Strong, large crushing ratio, high production efficiency, and wearing parts are made of high wear-resistant materials, which are more durable and can save maintenance costs.

PF1007 Impact Crusher

Limestone medium and fine crushing equipment, the crushed stone processed by jaw crushing need to be sent to the impact crusher for secondary crushing. The feeding particle size is 0-250mm, and the production capacity is 15-60t/h. The finished limestone stone has a good particle shape and is cubic, with low stone powder content and good quality.

At the same time, these devices are also suitable for granite, basalt, limestone, etc., with low operating cost, long service life, high degree of automation, and stable and reliable operation. Especially the impact crusher, a new type of crushing equipment, the equipment has high productivity, both shaping function, good finished product particle shape, long service life, energy-saving, and environmental protection.

Cone Crushing - High Capacity And Superior Quality. Long Working Life Of Quick-Wear Parts. Stone Crusher Rock Crushing Plant for Sale.

We offer rugged primary crushing plants for pre-crushing and secondary and tertiary crushing. Robust, optimum flow, low-wear, and maintenance-friendly chute systems. Call us now! Worldwide delivery.

Crawler Type Mobile Screening Plant, Crawler crusher, Crawler crushing and screening plant