|

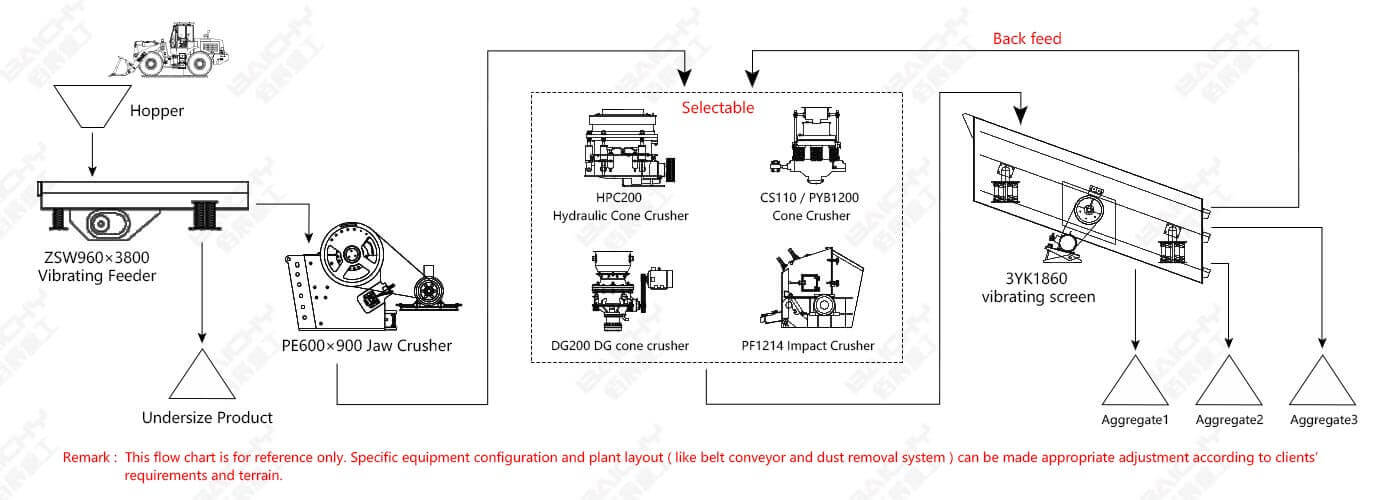

Equipment configuration

|

Hopper, ZSW960x3800 vibrating feeder, PE600x900 jaw crusher, HPC200/CS110 cone crusher(PF1214 impact crusher), Vibrating screen, Belt conveyor. |

|

Raw materials

|

This stone-crushing plant can crush more than 120 kinds of ore materials such as limestone, granite, basalt, Riverstone, and rocks. |

|

Feed Size

|

Less than 500mm |

|

Capacity

|

100-150t/h |

|

Finished product

|

3-100mm |

|

Application

|

Produce aggregate of limestone, granite, basalt, river stone, marble, iron ore, dolomite, quartz, slag etc, which is widely applied for hydropower, construction, highway, railway, airport runway, civil engineering projects and etc. |

|

Advantages

|

High production efficiency and low operating cost; Large output, uniform particle size of finished stones and good grain shape, which meets the requirements of national high-speed materials. |

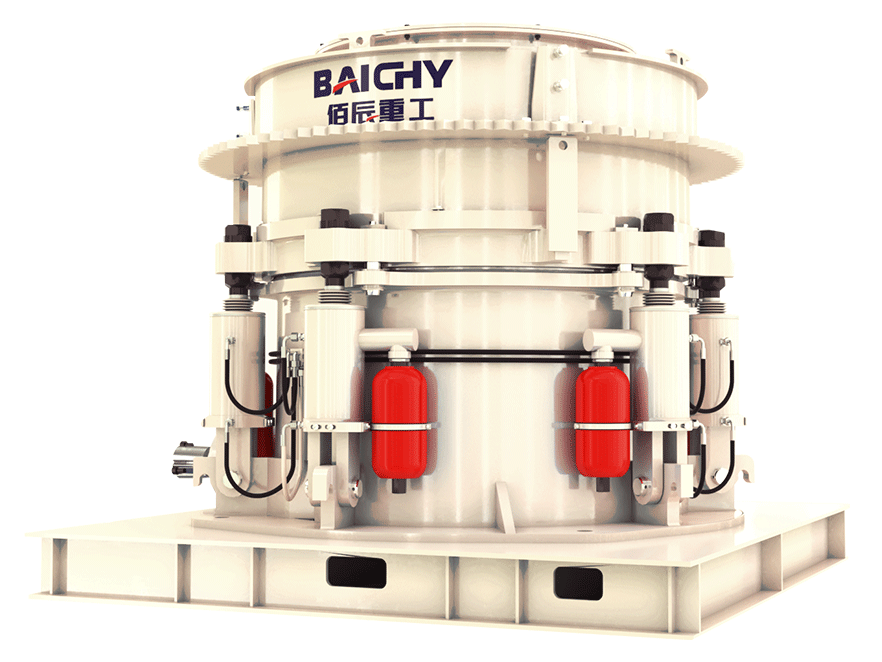

Hydraulic Cone Crusher integrates machinery, hydraulic pressure, electrics, automation, and intelligent control, which can be used for medium crushing, fine crushing, and ultra-fine crushing.

DG cone crusher is the type of single-cylinder hydraulic cone crusher. It is an ideal crusher machine to crush hard rocks or minerals for middle granular size crushing or fine granule size crushing.

In industrial production, belt conveyors can be used as the link between production machinery and equipment to form continuous production, so as to realize the continuity and automation of production links, improve productivity and reduce labor intensity.

The belt conveyor can be widely used in mining, metallurgy, coal, transportation, hydropower, and other departments to transport bulk materials or finished items.

▪ Jaw crusher, commonly used as primary crushing equipment, has a large crushing ratio, strong processing capacity, and low failure rate;

▪ The impact crusher can process medium and fine crushing of stone, which can effectively simplify the process flow, reduce the budget, high yield, and large output;

▪ Cone crusher is also the processing of medium and fine crushing of stone, with higher performance, stronger stability, higher yield, and uniform particle shape during operation, but the price will be higher than that of an impact crusher.

Cone Crushing - High Capacity And Superior Quality. Long Working Life Of Quick-Wear Parts. Stone Crusher Rock Crushing Plant for Sale.

We offer rugged primary crushing plants for pre-crushing and secondary and tertiary crushing. Robust, optimum flow, low-wear, and maintenance-friendly chute systems. Call us now! Worldwide delivery.

Crawler Type Mobile Screening Plant, Crawler crusher, Crawler crushing and screening plant