|

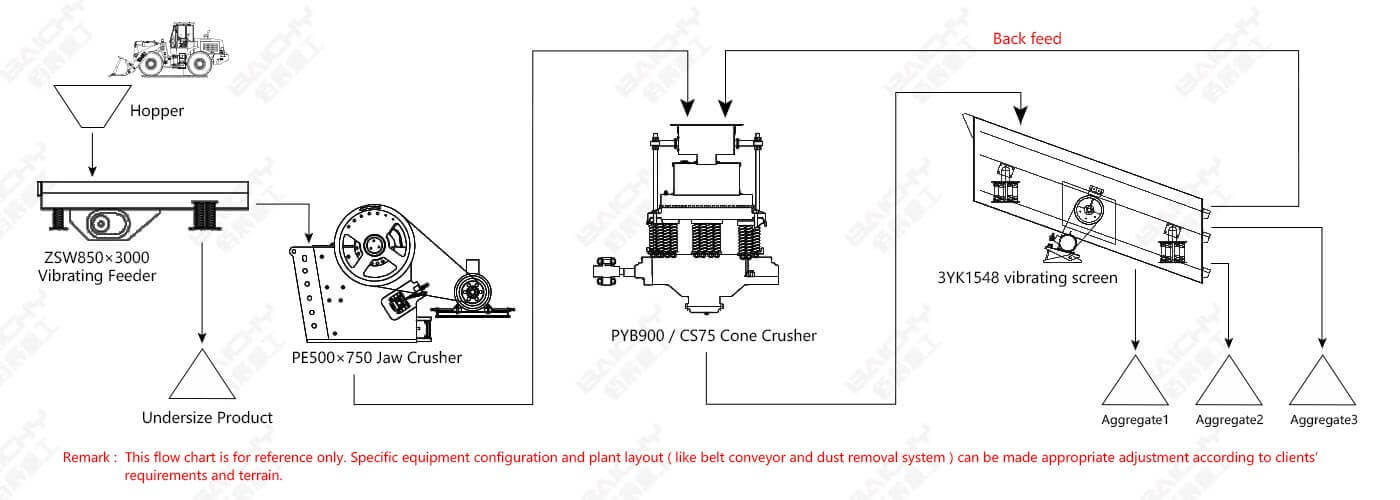

Equipment configuration

|

Hopper, vibrating feeder ZSW850x3000, jaw crusher PE500x750, cone crusher PYB900, vibrating screen YK series, belt conveyor. |

|

Raw materials

|

Crush and screen limestone, marble, granite, basalt, river gravel and other hard stone materials. |

|

Feed Size

|

Less than 425mm |

|

Capacity

|

80-100t/h |

|

Finished product

|

3-100mm |

|

Application

|

Produce sand & gravels with various granularities of limestone, granite, basalt, river stone, marble, iron ore, dolomite, quartz, slag etc, which is widely applied for hydropower, construction, highway, railway, airport runway, civil engineering projects and etc. |

|

Advantages

|

High production efficiency and low operating cost; Large output, uniform particle size of finished stones and good grain shape, which meets the requirements of national high-speed materials. |

In industrial production, belt conveyors can be used as the link between production machinery and equipment to form continuous production, so as to realize the continuity and automation of production links, improve productivity and reduce labor intensity.

The belt conveyor can be widely used in mining, metallurgy, coal, transportation, hydropower, and other departments to transport bulk materials or finished items.

The high hardness ores mainly include granite, marble, basalt, iron ore, copper ore, etc. In addition, shale, metal ores, etc. are all high-hardness stones.

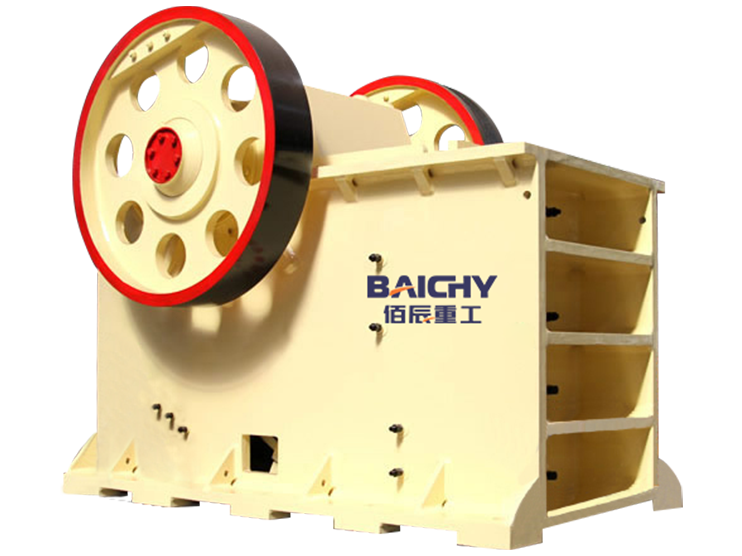

Wear-resistant crushing machinery is used for high-hardness stone crushing. The commonly used types are jaw crushers and cone crushers. There are two types of cone crushers: horizontal bar hydraulic cone crusher and multi-cylinder hydraulic cone crusher.

What is the technological process of producing stone from high hardness stone?

The production of high-hardness stones requires two processes of crushing and screening.

1.The crushing process is as follows: the large pieces of stone are sent to the jaw crusher through the feeder for coarse crushing, and then the crushed stone is sent to the cone crusher for fine crushing and crushed to the size of stones.

2.Screening process: Crushing is crushing large stones to the size of stones, and if you want stones of different sizes, you need screening equipment to complete them. The stone crushed by the cone crusher is sent to the vibrating screen through the conveying equipment. By setting the number of layers of the screen and the size of the screen hole, we can realize the production of different specifications.

Cone Crushing - High Capacity And Superior Quality. Long Working Life Of Quick-Wear Parts. Stone Crusher Rock Crushing Plant for Sale.

We offer rugged primary crushing plants for pre-crushing and secondary and tertiary crushing. Robust, optimum flow, low-wear, and maintenance-friendly chute systems. Call us now! Worldwide delivery.

Crawler Type Mobile Screening Plant, Crawler crusher, Crawler crushing and screening plant