|

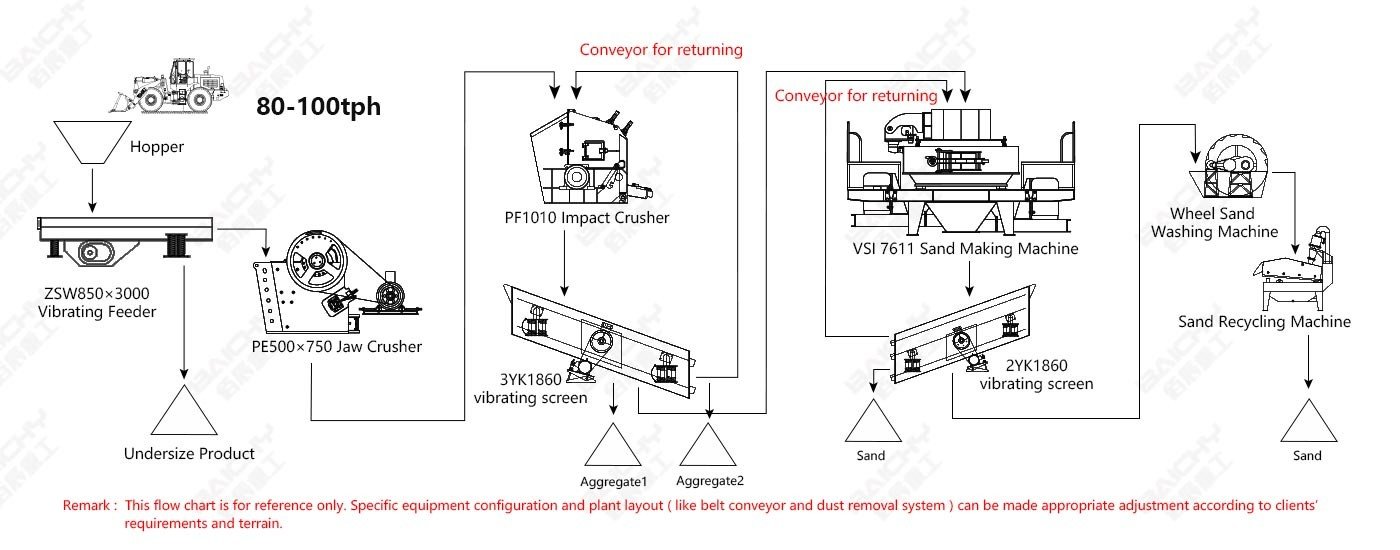

Equipment configuration

|

Hopper, ZSW850x3000 vibrating feeder, PE500x750 jaw crusher, PF1010 impact crusher (or cone crusher), VSI7611 sand making machine, Vibrating screen, Sand recycling machine, Belt conveyor. |

|

Raw materials

|

Limestone, Granite, Basalt, Quartz, River stone etc. |

|

Feed Size

|

Less than 425mm |

|

Finished product

|

Fine sand 0.25-0.35mm, medium sand 0.35-0.5mm, coarse sand 0.5mm. |

|

Capacity

|

50-100t/h |

|

Application

|

In sand quarry, mine, construction site, highway, road and bridge construction, concrete mixing station, water conservancy and hydropower, chemical industry and other industries. |

|

Advantages

|

High production efficiency and low operating cost; Multi-functions and Flexible application; Good shape of finished sand and fineness is adjustable. |

The vibrating feeder refers to a kind of equipment that uniformly and continuously transports block or granular materials from the silo to the receiving device, and can continuously and evenly feed the crusher.

In industrial production, belt conveyors can be used as the link between production machinery and equipment to form continuous production, so as to realize the continuity and automation of production links, improve productivity and reduce labor intensity.

The belt conveyor can be widely used in mining, metallurgy, coal, transportation, hydropower, and other departments to transport bulk materials or finished items.

The fine jaw crusher is called fine jaw crusher or fine crusher. It is a jaw crusher with a relatively small crushing cavity. Generally, the crushed material is uniform. The fine jaw crusher is a kind of rock crusher, which is mainly used for fine-crushing operations.

Cone Crushing - High Capacity And Superior Quality. Long Working Life Of Quick-Wear Parts. Stone Crusher Rock Crushing Plant for Sale.

We offer rugged primary crushing plants for pre-crushing and secondary and tertiary crushing. Robust, optimum flow, low-wear, and maintenance-friendly chute systems. Call us now! Worldwide delivery.

Crawler Type Mobile Screening Plant, Crawler crusher, Crawler crushing and screening plant