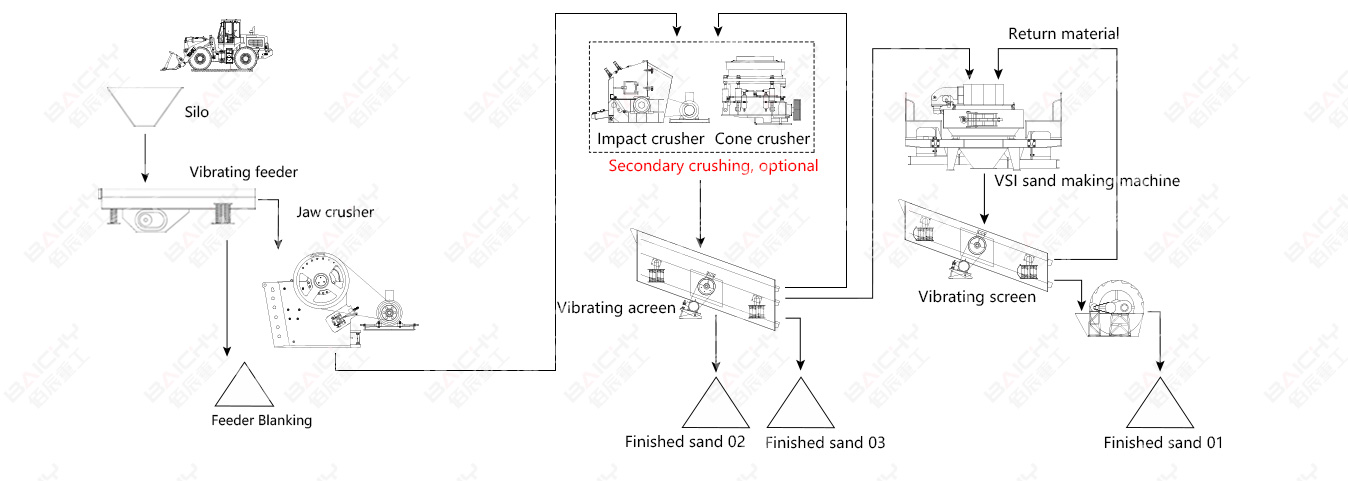

| Equipment configuration |

Hopper, ZSW960x3800 vibrating feeder, PE600x900 jaw crusher,PYB1200/CS110 cone crusher (or impact crusher), VSI9526 sand making machine, Vibrating screen, Sand recycling machine, Belt conveyor.

|

|

Raw materials

|

Limestone, Granite, Basalt, Quartz, River stone etc. |

|

Feed Size

|

Less than 500mm |

|

Finished product

|

Fine sand 0.25-0.35mm, medium sand 0.35-0.5mm, coarse sand 0.5mm |

|

Capacity

|

100-150t/h |

|

Application

|

In sand quarry, mine, construction site, highway, road and bridge construction, concrete mixing station, water conservancy and hydropower, chemical industry and other industries. |

|

Advantages

|

High production efficiency and low operating cost; Multi-functions and Flexible application; Good shape of finished sand and fineness is adjustable. |

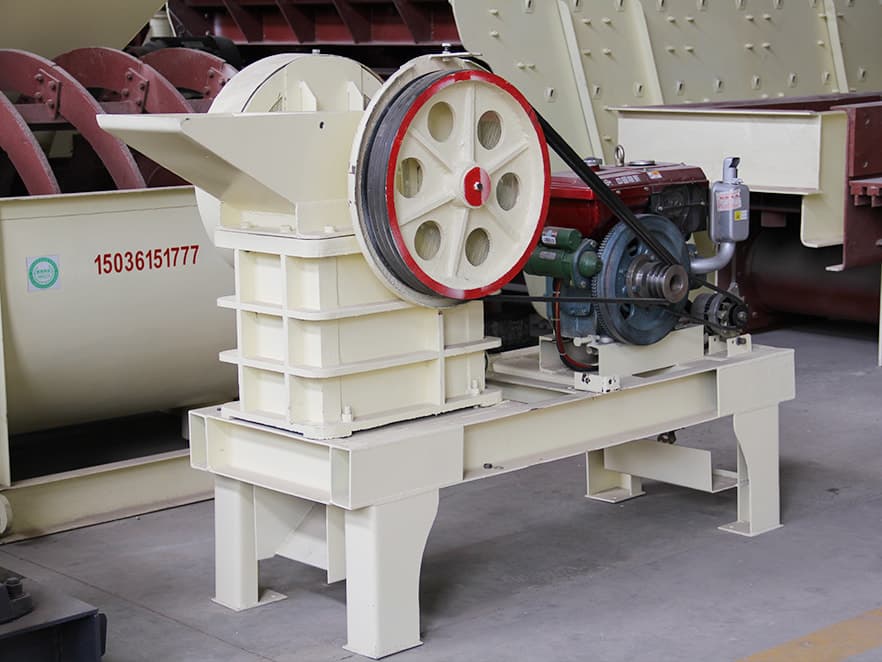

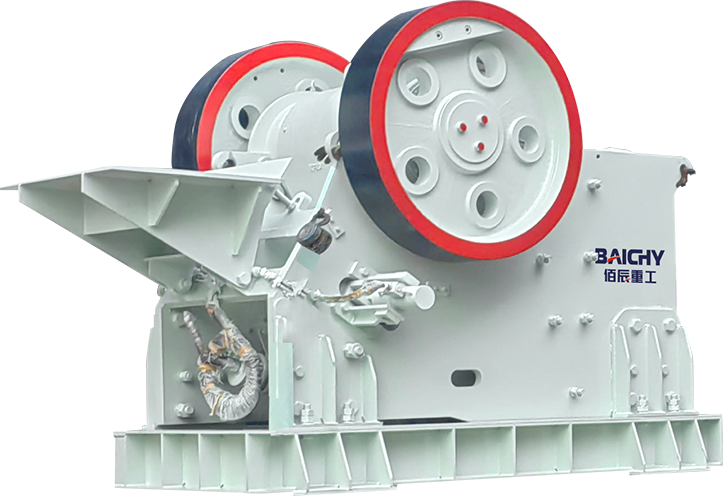

The jaw crusher is the preferred equipment for primary crushing. The output of the small jaw crusher is very small. If you don't need to process a lot of materials, a small jaw crusher can meet the demand. Its hot-selling models are PE200X350, PE250X400, and PE400X600.

DG cone crusher is the type of single-cylinder hydraulic cone crusher. It is an ideal crusher machine to crush hard rocks or minerals for middle granular size crushing or fine granule size crushing.

Cone Crushing - High Capacity And Superior Quality. Long Working Life Of Quick-Wear Parts. Stone Crusher Rock Crushing Plant for Sale.

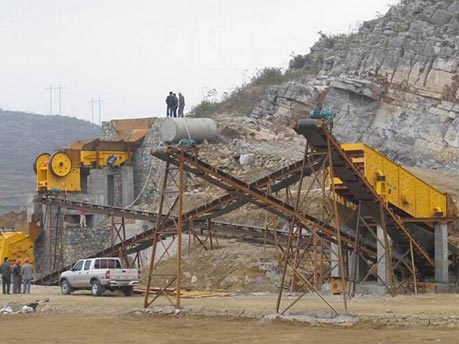

We offer rugged primary crushing plants for pre-crushing and secondary and tertiary crushing. Robust, optimum flow, low-wear, and maintenance-friendly chute systems. Call us now! Worldwide delivery.

Crawler Type Mobile Screening Plant, Crawler crusher, Crawler crushing and screening plant