| Equipment list | Calcium carbonate mill, jaw crusher, bucket elevator, electromagnetic vibrating feeder |

| Raw materials | Calcium carbonate |

| Mohz hardness | Mohs about 7 degrees |

| Feeding size | <40mm |

| Capacity | 0.5-60t/h |

| Output size | 30-425mesh |

| Application | Such as stone flour, barite, bentonite, calcium carbonate, clinker, coal, dolomite, lead oxide, limestone, marble, quartz, ultrafine. |

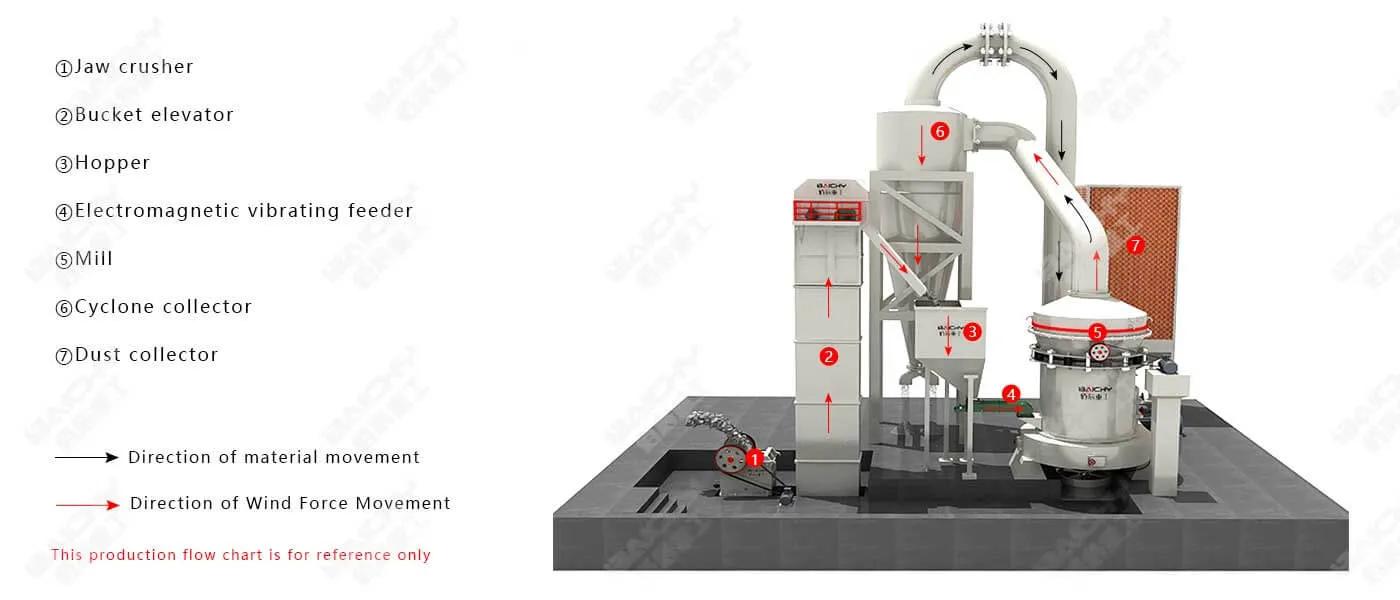

The first stage: Crushing

The Calcium carbonate is crushed by the crusher to the feed fineness (15mm-50mm) that can enter the mill.

The second stage: Milling

The crushed small pieces of bentonite are sent to the silo by the elevator, and then sent to the grinding chamber of the mill by the vibrating feeder for grinding

The third stage: Grading

The powdered material is separated by the classifier, the unqualified powder will be returned to the grinding mill chamber for re-milling。

The fourth stage: Collecting

Fine powder complies with the fineness and airflow go through the pipe into the dust collector for separation and collection. The finished powder will be transmitted to bucket elevator by screw conveyor and lifted into Silo for storage by Bucket elevator , then packed uniformly by powder tanker or automatic packing machine.

Energy saving

Energy saving Easy to operate

Easy to operate Quality assurance

Quality assurance Environmental friendly

Environmental friendly

Raymond Mill adopts the advanced structure of similar products at home and abroad and is updated and improved on the basis of Raymond Mills in the same industry. Compared with ball mills, this equipment has higher efficiency, lower power consumption, smaller floor space, and less one-time investment. It is mainly used in calcium carbonate crushing processing, gypsum powder processing, power plant desulfurization, non-metallic ore pulverization, coal powder preparation, etc.

YGM high-pressure roller mill is an efficient, environmentally friendly, and adaptable grinding equipment. It is especially suitable for grinding various non-metallic minerals and can meet the grinding needs of different industries. Users can choose appropriate models and specifications according to their own production needs, and use and maintain them in strict accordance with operating procedures.

MTW trapezoidal European version grinding equipment is a high-efficiency grinding equipment that combines advanced European technology and design concepts. It adopts a number of the latest national patented technologies, such as bevel gear integral transmission, internal thin oil lubrication system, arc-shaped air duct, etc., giving the equipment significant advantages in performance, efficiency, and environmental protection.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery